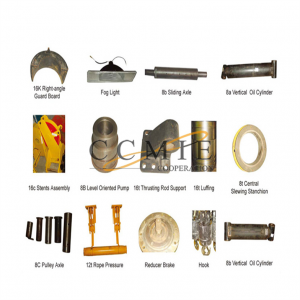

Wheel loader brake pads parts for XCMG Liugong wheel loader

brake pads

Because there are many kinds of spare parts, we can’t display them all on the website. Please feel free to contact us for specific ones.

advantage

1. We supply both original and aftermarket products for you

2. From the manufacturer to the customer directly, saving your cost

3. Stable stock for normal parts

4. In Time Delivery Time, with competitive shipping cost

5. Professional and on time after service

packing

Carton Boxes, or according to clients’ request.

description

Brake pads, also called automobile brake pads, refer to the friction material fixed on the brake drum or brake disc that rotates with the wheels. The friction linings and friction linings are subjected to external pressure and generate friction to achieve the purpose of vehicle deceleration.

Automobile brake pads are generally composed of steel plate, adhesive insulation layer and friction block. The steel plate must be painted to prevent rust. The SMT-4 furnace temperature tracker is used to detect the temperature distribution of the coating process to ensure the quality.

The working principle of the brake is mainly from friction. The friction between the brake pads and the brake discs (drums) and the tires and the ground is used to convert the kinetic energy of the vehicle into frictional heat energy to stop the car. A good and efficient brake system must provide stable, sufficient and controllable braking force, and have good hydraulic transmission and heat dissipation capabilities to ensure that the force exerted by the driver from the brake pedal can be fully and effectively transmitted to the master cylinder And each sub-cylinder, and to avoid hydraulic failure and brake degradation caused by high heat. The brake system on the car is divided into two categories: disc and drum, but apart from the cost advantage, drum brakes are far less efficient than disc brakes.

“Friction” refers to the movement resistance between the contact surfaces of two relatively moving objects. The frictional force (F) is proportional to the product of the friction coefficient (μ) and the vertical normal pressure (N) on the friction bearing surface, expressed as a physical formula: F=μN. For the brake system: (μ) refers to the friction coefficient between the brake pad and the brake disc, and N is the force exerted by the brake caliper piston on the brake pad (Pedal Force). The greater the friction coefficient, the greater the friction generated, but the friction coefficient between the brake pad and the disc will change due to the high heat generated after friction, that is to say, the friction coefficient (μ) changes with temperature However, each type of brake pad has a different friction coefficient change curve due to the difference in material. Therefore, different brake pads will have different optimal operating temperatures and applicable operating temperature ranges. This is when you buy brake pads. What you must know.

Transmission of braking force

The force exerted by the brake caliper piston on the brake pads is called: Pedal Force. After the driver’s force on the brake pedal is amplified by the lever of the pedal mechanism, the force is amplified by the principle of vacuum pressure difference via a power boost, which is used to push the brake master cylinder. The hydraulic pressure generated by the brake master cylinder utilizes the liquid incompressible power transmission effect, which is transmitted to each sub-cylinder via the brake hose, and the pressure is amplified by the “Pascal principle” to push the piston of the sub-cylinder to exert force on the brake pads. “Pascal’s Law” (Pascal’s Law) means that the liquid pressure at any position in a closed container is the same.

The pressure is obtained by dividing the applied force by the force-receiving area. When the pressure is equal, we can use to change the ratio of the applied and force-receiving areas to achieve the effect of power amplification (P1=F1/A1=F2/A2=P2) . Used in the brake system, the ratio of the pressure of the master cylinder to the cylinder is the ratio of the piston area of the master cylinder to the piston area of the cylinder.

Equipped with: ABS

ABS: Anti-lock Brake System, as the name implies, is “Anti-lock Brake System”. Everyone knows that the greatest braking effect occurs immediately before the tires are locked. If the braking force can be kept in balance with the tire friction, the greatest braking effect will be obtained. When the braking force of the brake is greater than the friction of the tire, it will cause the tire to lock up. Once the tire locks up, the friction between the tire and the ground will change from “static friction” to “dynamic friction”. Not only the friction is greatly reduced, but the steering is lost. Tracking ability. Because the tire lockup is the result of the comparison between the braking force and the friction force between the tire and the ground, that is to say, the limit of whether the tire locks up while the car is running depends on the characteristics of the tire itself, the condition of the road surface, the positioning angle, and the tire pressure.

The characteristics of the suspension system are “different from time to time”. ABS uses vehicle speed sensors installed on four wheels to determine whether the tires are locked, eliminating the uncertain factors of the human senses, and accurately controlling the timely release of the hydraulic pressure of the brake cylinder to prevent the brakes from locking up. . Most of the current ABS adopts a design that can continuously step on and release 12 to 60 times per second (12~60 Hz). Compared with the 3 to 6 times of top professional racers, it is an ultra-high level of performance.

The higher the frequency of stepping, the more The braking force can be maintained at the edge closer to the limit. The accuracy and reliability that ABS can achieve has exceeded human limits, so we say: ABS is the most value-for-money equipment when buying a car. Especially the relative danger of Air-Bag.

our warehouse

Pack and ship

- Aerial Boom Lift

- China Dump Truck

- Cold Recycler

- Cone Crusher Liner

- Container Side Lifter

- Dadi Bulldozer Part

- Forklift Sweeper Attachment

- Hbxg Bulldozer Parts

- Howo Engine Parts

- Hyundai Excavator Hydraulic Pump

- Komatsu Bulldozer Parts

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Liugong Bulldozer Parts

- Sany Concrete Pump Spare Parts

- Sany Excavator Spare Parts

- Shacman Engine Parts

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Connecting Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- Shantui Bulldozer Lifting Cylinder Repair Kit

- Shantui Bulldozer Parts

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Shantui Bulldozer Spare Parts

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- Shantui Dozer Tilt Cylinder Repair Kit

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Bearing Sleeve

- Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Sinotruk Engine Parts

- Tow Truck

- Xcmg Bulldozer Parts

- Xcmg Bulldozer Spare Parts

- Xcmg Hydraulic Lock

- Xcmg Transmission

- Yuchai Engine Parts