Bucket teeth excavator spare parts for sale

bucket teeth

Because there are many kinds of spare parts, we can’t display them all on the website. Please feel free to contact us for specific ones.

Advantage

1. We supply both original and aftermarket products for you

2. From the manufacturer to the customer directly, saving your cost

3. Stable stock for normal parts

4. In Time Delivery Time, with competitive shipping cost

5. Professional and on time after service

Packing

Carton Boxes, or according to clients’ request.

description

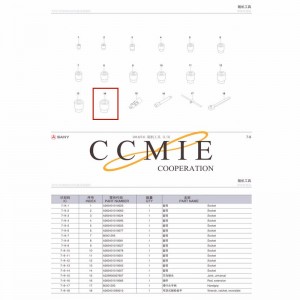

Bucket teeth of excavators are important parts of excavators, similar to human teeth, but also vulnerable parts. They are combined bucket teeth composed of a tooth seat and a tooth tip, and the two are connected by a pin shaft. Because the part of the bucket tooth wear and failure is the tooth tip, just replace the tooth tip.

Classified according to the environment in which the bucket teeth of the excavator are used. Excavator bucket teeth can be divided into rock teeth (used for iron ore, quarry, etc.), earthmoving teeth (used for digging soil, sand, etc.), and tapered teeth (used for coal mines).

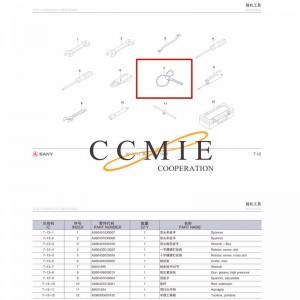

Process flow

The technological process of bucket teeth: sand casting, forging and precision casting.

Sand casting: the lowest cost, while the level of craftsmanship and the quality of bucket teeth are not as good as precision casting and forging die casting.

Forging: the highest cost and the best craftsmanship and tooth quality.

Precision casting: The cost is moderate but the requirements for raw materials are very strict, and the technological level is relatively high. Due to the ingredients, some precision casting bucket teeth have a wear resistance and quality even exceeding that of forging casting bucket teeth. At present, precision casting bucket teeth is the mainstream manufacturing process for bucket teeth on the market.

Forging bucket teeth use forging machinery to apply pressure to special metal blanks, extruding and forming at high temperatures, refine the crystal material in the forging, and make it plastically deformed to obtain certain mechanical properties. The metal can improve its structure after forging. , Which can ensure that the forged bucket teeth have good mechanical properties, more wear resistance and longer service life. The casting is to melt the metal at a high temperature, add auxiliary materials, inject the model, and obtain the casting after solidification. The casting produced by this process is prone to pores and trachoma. Its mechanical properties, wear resistance and service life are relatively good. Forgings are low.

The replacement method of excavator bucket teeth:

1. Bucket teeth should be kept sharp.

2. The teeth on both sides of the bucket generally wear out faster than the teeth in the middle of the bucket. When the teeth on both sides are worn much shorter than the teeth in the middle, the positions of the teeth in the middle and on both sides can be interchanged and continue to be used. If the difference between the length of the tooth at the center and the tooth at both ends reaches 2 to 3 cm, it should be replaced.

3. If the difference between the length of the tooth at the center and the length of the tooth at both ends reaches 2 to 3 cm, it should be replaced. Please replace the bucket teeth in time.

4. Visually inspect the looseness and wear of the bucket teeth before working every day. If the wear of the bucket teeth exceeds the use limit, it will not only damage the tooth seat and the bucket, but also affect the efficiency of excavation and reduce production.

our warehouse

Pack and ship

- Aerial Boom Lift

- China Dump Truck

- Cold Recycler

- Cone Crusher Liner

- Container Side Lifter

- Dadi Bulldozer Part

- Forklift Sweeper Attachment

- Hbxg Bulldozer Parts

- Howo Engine Parts

- Hyundai Excavator Hydraulic Pump

- Komatsu Bulldozer Parts

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Liugong Bulldozer Parts

- Sany Concrete Pump Spare Parts

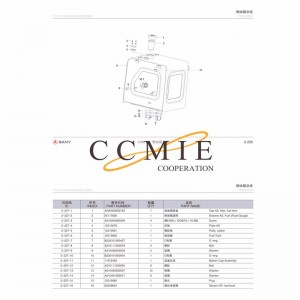

- Sany Excavator Spare Parts

- Shacman Engine Parts

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Connecting Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- Shantui Bulldozer Lifting Cylinder Repair Kit

- Shantui Bulldozer Parts

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Shantui Bulldozer Spare Parts

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- Shantui Dozer Tilt Cylinder Repair Kit

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Bearing Sleeve

- Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Sinotruk Engine Parts

- Tow Truck

- Xcmg Bulldozer Parts

- Xcmg Bulldozer Spare Parts

- Xcmg Hydraulic Lock

- Xcmg Transmission

- Yuchai Engine Parts