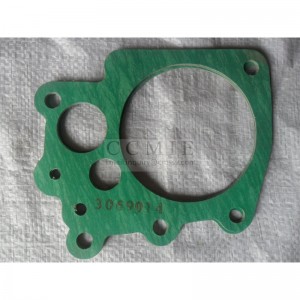

Road roller fan spare parts for XCMG road roller

Fan

Because there are many kinds of spare parts, we can’t display them all on the website. Please feel free to contact us for specific ones.

Advantage

1. We supply both original and aftermarket products for you

2. From the manufacturer to the customer directly, saving your cost

3. Stable stock for normal parts

4. In Time Delivery Time, with competitive shipping cost

5. Professional and on time after service

Packing

Carton Boxes, or according to clients’ request.

description

Fan also known as “turbofan engine”. It refers to a gas turbine engine in which the gas injected by the nozzle and the air discharged by the fan produce a reaction thrust. It consists of a compressor, a combustion chamber, a high-pressure turbine (to drive the compressor), a low-pressure turbine (to drive a fan) and an exhaust system. The first three parts are called the “core engine”. The available energy in the gas flowing out of the core engine is used to drive the low-pressure turbine to drive the fan, and the other part is used in the nozzle to accelerate the ejected gas. The bypass ratio is closely related to fuel consumption. The first generation of turbofan engines that appeared in the late 1950s had relatively low bypass ratio, compressor boost ratio and gas temperature before the turbine.

The structure of the FAN is actually that there are 1-2 low-pressure (low-speed) turbines added to the rear of the turbojet engine. These turbines drive a certain number of fans and consume a part of the gas exhaust kinetic energy of the turbojet engine (core engine). , Thereby further reducing the gas discharge speed. Part of the air flow sucked in by the fan is sent to the compressor (termed “internal duct” in terminology), just like an ordinary jet engine, and the other part is directly discharged from the periphery of the turbojet engine casing (“outer duct”). Therefore, the gas energy of the turbofan engine is distributed to the two exhaust air flows generated by the fan and the combustion chamber respectively. At this time, in order to improve thermal efficiency and increase the temperature in front of the turbine, more fuel gas energy can be transferred to the outer duct airflow through the low-pressure turbine-driven fan through proper turbine structure and increased fan diameter, thereby avoiding a significant increase in exhaust velocity. In this way, thermal efficiency and propulsion efficiency have been balanced, and the efficiency of the engine has been greatly improved. Higher efficiency means lower fuel consumption and longer range of the aircraft. However, the large fan diameter increases the windward area of the engine, so turbofan engines with a bypass ratio greater than 0.3 are not suitable for supersonic cruise flight. Although the turbofan engine reduces the exhaust speed, it does not reduce the thrust, because reducing the exhaust speed increases the (external) exhaust flow. From the perspective of bypass ratio, turbofan engine is a compromise between turbojet engine and turboprop engine.

Our-warehouse1

Pack and ship

- Aerial Boom Lift

- China Dump Truck

- Cold Recycler

- Cone Crusher Liner

- Container Side Lifter

- Dadi Bulldozer Part

- Forklift Sweeper Attachment

- Hbxg Bulldozer Parts

- Howo Engine Parts

- Hyundai Excavator Hydraulic Pump

- Komatsu Bulldozer Parts

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Liugong Bulldozer Parts

- Sany Concrete Pump Spare Parts

- Sany Excavator Spare Parts

- Shacman Engine Parts

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Connecting Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- Shantui Bulldozer Lifting Cylinder Repair Kit

- Shantui Bulldozer Parts

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Shantui Bulldozer Spare Parts

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- Shantui Dozer Tilt Cylinder Repair Kit

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Bearing Sleeve

- Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Sinotruk Engine Parts

- Tow Truck

- Xcmg Bulldozer Parts

- Xcmg Bulldozer Spare Parts

- Xcmg Hydraulic Lock

- Xcmg Transmission

- Yuchai Engine Parts