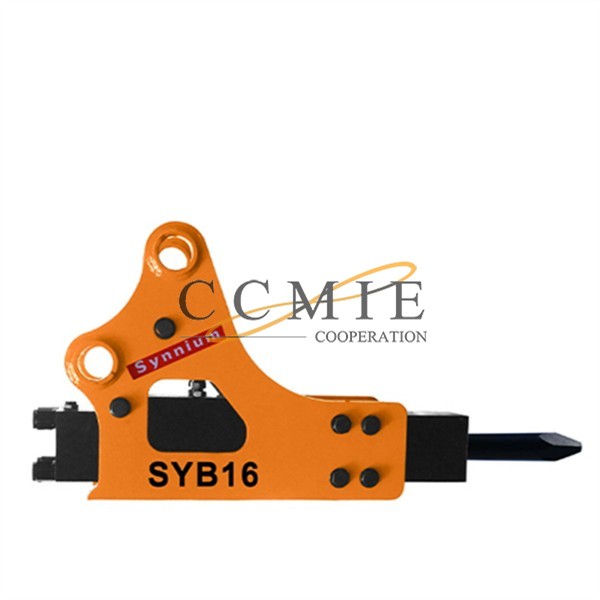

The breaker hammer is one of the most commonly used attachments for excavators. Crushing operations are often required in demolition, mining, and urban construction. How to properly maintain the breaker?

Since the working conditions of the breaker are very harsh, correct maintenance can reduce machine failures and extend the service life of the machine. In addition to correct maintenance of the main machine, you should also pay attention to the following points:

(1) Appearance inspection

Check whether the relevant bolts are loose; whether the connecting pins are excessively worn; check whether the gap between the drill rod and its bushing is normal, whether there is oil leakage in the breaker hammer and the pipeline.

(2) Lubrication

The lubrication points of the working equipment should be lubricated before operation and after 2 days of continuous operation.

(3) Replacement and inspection of hydraulic oil

The hydraulic oil of construction machinery using breakers should be replaced every 600 hours, and the temperature of the hydraulic oil should be checked to be below 800°C. The choice of hydraulic oil determines the efficiency of the hydraulic breaker. It is recommended to use anti-wear 68# hydraulic oil in summer and 46# anti-wear hydraulic oil in winter. Please select hydraulic oil as appropriate according to the specific working environment of the equipment. The use of contaminated hydraulic oil will cause the main body of the breaker and construction machinery to malfunction and damage accessories, so please pay special attention to the grease of the hydraulic oil.

If you need to buy a breaker or excavator, you can contact us. CCMIE not only sells various spare parts, but also construction machinery.

Post time: Mar-19-2024