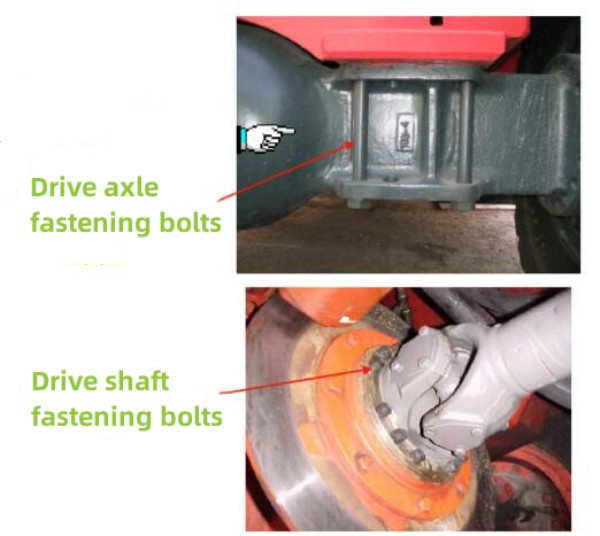

1. Check the tightness of the drive axle fixing bolts

Why check?

Loose bolts are prone to breakage under load and vibration. The breakage of the fixing bolts will cause serious damage to the equipment and even casualties.

Driving axle bolt tightness

Torque 2350NM

Transmission shaft

Retighten

2. Check the drive axle and brake components for oil leakage

Check content:

* Oil immersed disc brake and connecting oil pipe.

* Parking brake system and connecting oil pipe.

* Differentials and drive wheels, drive axles.

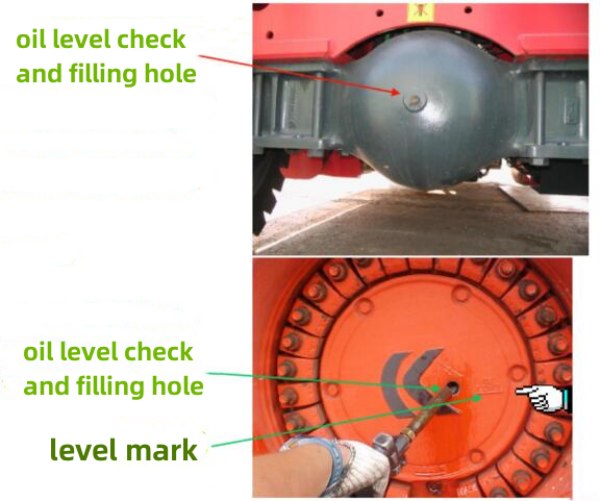

3. Check the oil quantity of drive axle differential and planetary gearbox

Method:

Move the locomotive forward so that the mark next to the oil filler hole on the hub is in a horizontal position. (When checking the oil level of the planetary gearbox) Remove the oil plug and check the oil level. Add engine oil to the oil filler hole if necessary.

Work content:

* Change oil

* Check the old gear oil and metal particles in the oil drain plug to judge the damage of internal parts.

Notice: GL-5. SAE 80/ W 140 gear oil should be used.

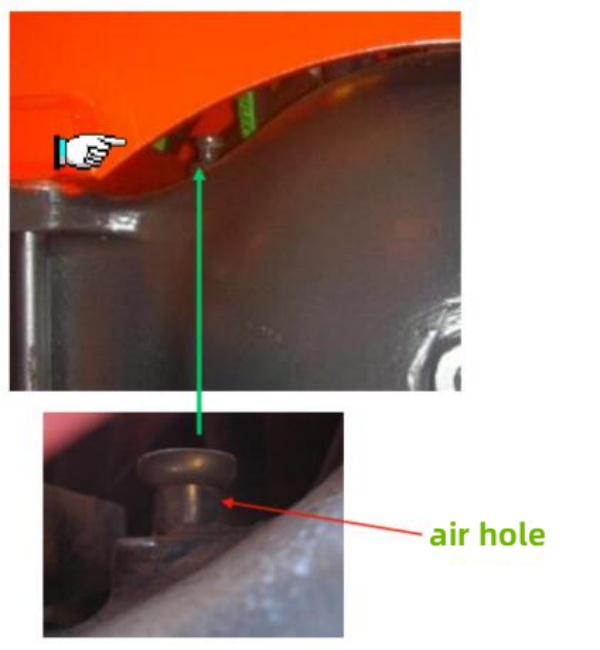

4. Clean the vent connector

Why clean?

* Let steam escape from the transaxle.

*Prevent pressure rise in transaxle. If the pressure in the transaxle increases, it may cause oil leakage from fragile parts such as oil seals.

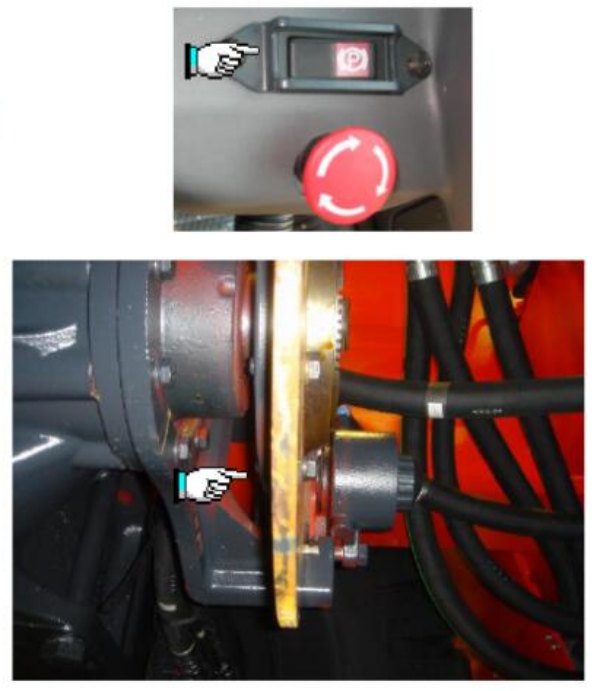

5. Check the handbrake pads and handbrake function

Method:

* Start the engine and let the engine run until the accumulator is charged.

* Stop the engine and turn the ignition key to position I.

* Release the parking brake.

* Check if the parking brake caliper can move on the bracket.

* Check the clearance between the brake lining and the brake disc and adjust if necessary.

Notice:

The vehicle may move and there is a risk of crushing injuries. Chock the wheels to ensure that the vehicle does not move when the parking brake is released to avoid accidents.

Post time: May-24-2023