The breaker hammer is one of the important accessory tools of excavators and loaders. It is widely used in road crushing, house demolition, bridge demolition, rock crushing in mines and other fields. So how much do you know about the types of breakers?

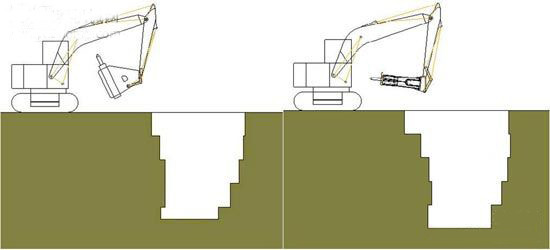

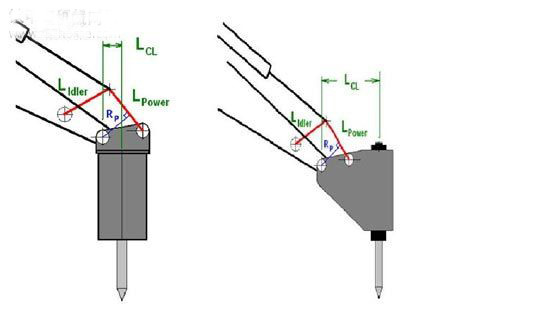

According to different classification standards, the types of breakers are different. According to the appearance and structure, they can generally be divided into two types: triangular type and upright type. So what is the difference between these two types of breakers? The following mainly distinguishes from four aspects.

(1) Different appearance and shape

From the appearance, two types of breakers can be distinguished at a glance, one is an upright bracket and the other is a triangular bracket.

(2) Different scope of work

The working range of the two types is different. Generally, the hammer length of the triangular breaker is shorter than that of the upright breaker, and the installation point of the upright breaker and the excavator is relatively high. For horizontal and grooved working surfaces, the working range obtained by the vertical breaker is relatively large, reducing movement during operation.

(3) Differences in construction applications

Because the installation point of the triangular breaker and the excavator arm is relatively low, the triangular breaker is easy to lift during demolition operations; the upright breaker has a larger direct force and has obvious advantages in vertical strikes. Especially the breaking of stones.

(4) Other differences

Of course, there are other differences between the two. For example, the vertical type breaker has a better field of view than the triangular type, and the operator can clearly see the material. In addition, the vertical breaker can work closer to the machine and has a larger horizontal operating range; the triangular breaker works farther away from the machine, requiring the breaker to be small and light to maintain the stability of the machine.

Summary: The above is just a brief introduction to the differences between triangular and vertical breakers. Of course, no matter what kind of breakers, the ultimate purpose is the same, and they are all used for crushing.

If you need to purchase breakers or related excavators and loaders, you can contact us. CCMIE not only sells various spare parts, but also construction machinery.

Post time: Mar-19-2024