Planetary shaft assembly spare part for XCMG SINO HOWO truck

Planetary shaft assembly

Because there are many kinds of spare parts, we can’t display them all on the website. Please feel free to contact us for specific ones.

advantage

1. We supply both original and aftermarket products for you

2. From the manufacturer to the customer directly, saving your cost

3. Stable stock for normal parts

4. In Time Delivery Time, with competitive shipping cost

5. Professional and on time after service

packing

Carton Boxes, or according to clients’ request.

description

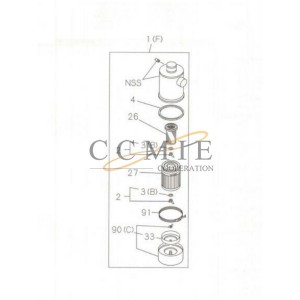

Planetary gear means that the axis of rotation is not fixed and is mounted on a rotatable bracket. In addition to planetary gears that can rotate around their own rotating shafts like fixed-axis gears, their rotating shafts also rotate with the blue carrier (called the planet carrier) around the axis (A-A) of other gears. The rotation around its own axis is called “rotation”, and the rotation around the axis of other gears is called “revolution”, just like the planets in the solar system, hence the name.

The planetary gear mechanism is divided into single planetary row and double planetary row according to the number of planetary gears installed on the planet carrier.

Compared with ordinary gear transmission, planetary gear transmission has many unique advantages. The most notable feature is that power can be split when transmitting power, and the input shaft and output shaft are on the same horizontal line. Therefore, planetary gear transmission has been widely used in reducers, speed increasers and speed change devices in various mechanical transmission systems. In particular, it has been widely used in aircraft and vehicles (especially heavy vehicles) because of its “high load and large transmission ratio” characteristics. [1] Planetary gears also play a great role in the torque transmission of the engine. Since the characteristics of the engine’s speed and torque are quite different from the demands of road driving, the above-mentioned characteristics of planetary gears can be used to convert the power of the engine to the drive wheels. Automatic transmissions in automobiles also use these characteristics of planetary gears to obtain different transmission ratios by changing the relative motion relationship of various components through clutches and brakes.

However, due to the complex structure and working conditions of planetary gears, the problems of vibration and noise are also prominent. It is extremely prone to failure phenomena such as gear tooth fatigue pitting, tooth root cracks and even gear teeth or shaft fracture, which affects the operation accuracy of the equipment. Transmission efficiency and service life.

The simple (single-row) planetary gear mechanism is the basis of the transmission mechanism. Usually, the transmission mechanism of an automatic transmission is composed of two or more rows of planetary gear mechanisms. The simple planetary gear mechanism includes a sun gear, several planetary gears and a gear ring. The planetary gears are supported by the fixed shaft of the planet carrier, allowing the planetary gears to rotate on the supporting shaft. The planetary gear and the adjacent sun gear and ring gear are always in constant meshing state, and helical gears are usually used to improve the stability of work.

In a simple planetary gear mechanism, the sun gear is located at the center of the planetary gear mechanism. The sun gear and the planetary gear are always meshed, and the two external gears mesh in opposite directions. Just as the sun is located in the center of the solar system, the sun wheel is also named for its location. In addition to the planetary gear can rotate around the planet carrier supporting shaft, under some working conditions, it will also rotate around the central axis of the sun gear driven by the planet carrier, just like the rotation of the earth and the revolution around the sun. When this happens, it is called the transmission mode of the planetary gear mechanism. In the entire planetary gear mechanism, if the rotation of the planetary gears exists, but the planet carrier is fixed, this kind of transmission similar to the parallel shaft type is called fixed shaft transmission. The ring gear is an internal gear, which is constantly meshed with the planetary gear, and the internal gear meshes with the external gear, and the direction of rotation between the two is the same. The number of planetary gears depends on the design load of the transmission. There are usually three or four. The more the number, the greater the load.

A simple planetary gear mechanism is usually called a three-component mechanism. The three components refer to the sun gear, the planet carrier, and the ring gear. If the three components are to determine the mutual motion relationship, in general, you need to fix one of the components first, then determine who is the active part, and determine the speed and direction of rotation of the active part. As a result, the speed and direction of rotation of the passive part are determined.

Our-warehouse1

Pack and ship

- Aerial Boom Lift

- China Dump Truck

- Cold Recycler

- Cone Crusher Liner

- Container Side Lifter

- Dadi Bulldozer Part

- Forklift Sweeper Attachment

- Hbxg Bulldozer Parts

- Howo Engine Parts

- Hyundai Excavator Hydraulic Pump

- Komatsu Bulldozer Parts

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Liugong Bulldozer Parts

- Sany Concrete Pump Spare Parts

- Sany Excavator Spare Parts

- Shacman Engine Parts

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Connecting Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- Shantui Bulldozer Lifting Cylinder Repair Kit

- Shantui Bulldozer Parts

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Shantui Bulldozer Spare Parts

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- Shantui Dozer Tilt Cylinder Repair Kit

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Bearing Sleeve

- Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Sinotruk Engine Parts

- Tow Truck

- Xcmg Bulldozer Parts

- Xcmg Bulldozer Spare Parts

- Xcmg Hydraulic Lock

- Xcmg Transmission

- Yuchai Engine Parts