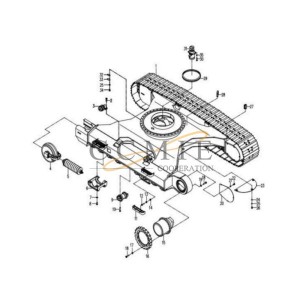

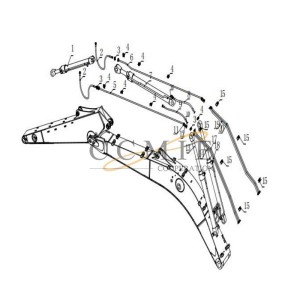

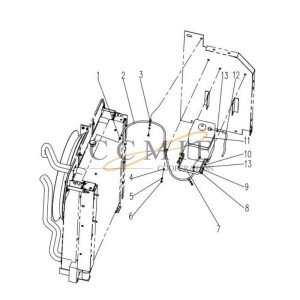

Track roller spare parts for excavator

track roller

Because there are many kinds of spare parts, we can’t display them all on the website. Please feel free to contact us for specific ones.

Advantage

1. We supply both original and aftermarket products for you

2. From the manufacturer to the customer directly, saving your cost

3. Stable stock for normal parts

4. In Time Delivery Time, with competitive shipping cost

5. Professional and on time after service

Packing

Carton Boxes, or according to clients’ request.

description

The track roller is used to support the weight of the excavator, while rolling on the track (rail link) or the track surface of the track. It is also used to limit the track and prevent lateral slippage. When the excavator turns, the rollers force the track to slip on the ground.

The function of the track roller is to transmit the weight of the locomotive unit to the ground and roll on the track. In order to prevent derailment, the support rollers should also be able to prevent the crawler from causing lateral relative movement to it.

The support wheels often work in mud, water, ash, and sand, and are subject to strong impacts. The working conditions are extremely harsh and the rims are easy to wear. The requirements for the track rollers are: wear-resistant rims, reliable bearing seals, and low rolling resistance.

Problems

(1)Wheel body wear. The reason for this situation is that the steel used is unqualified or the hardness of the material during heat treatment is low, and the wear resistance is insufficient;

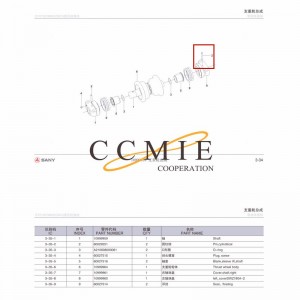

(2) Oil leakage. The bearing wheel shaft has been rotating through the shaft sleeve, and the wheel body needs to be lubricated by adding oil, but if the sealing ring is not good, it is easy to cause oil leakage, so that the shaft and the shaft sleeve are easy to wear without lubrication. The product cannot be used. The reasons for oil leakage are as follows: 1. Unqualified floating oil seal; 2. Insufficient roundness of the product bushing; 3. Insufficient luster of the support shaft; 4. Gear oil not up to standard; 5. Processing size tolerance and so on. The above-mentioned problems will cause oil leakage from the track roller.

Our-warehouse1

Pack and ship

- Aerial Boom Lift

- China Dump Truck

- Cold Recycler

- Cone Crusher Liner

- Container Side Lifter

- Dadi Bulldozer Part

- Forklift Sweeper Attachment

- Hbxg Bulldozer Parts

- Howo Engine Parts

- Hyundai Excavator Hydraulic Pump

- Komatsu Bulldozer Parts

- Komatsu Excavator Gear Shaft

- Komatsu Pc300-7 Excavator Hydraulic Pump

- Liugong Bulldozer Parts

- Sany Concrete Pump Spare Parts

- Sany Excavator Spare Parts

- Shacman Engine Parts

- Shantui Bulldozer Clutch Shaft

- Shantui Bulldozer Connecting Shaft Pin

- Shantui Bulldozer Control Flexible Shaft

- Shantui Bulldozer Flexible Shaft

- Shantui Bulldozer Lifting Cylinder Repair Kit

- Shantui Bulldozer Parts

- Shantui Bulldozer Reel Shaft

- Shantui Bulldozer Reverse Gear Shaft

- Shantui Bulldozer Spare Parts

- Shantui Bulldozer Winch Drive Shaft

- Shantui Dozer Bolt

- Shantui Dozer Front Idler

- Shantui Dozer Tilt Cylinder Repair Kit

- Shantui Sd16 Bevel Gear

- Shantui Sd16 Brake Lining

- Shantui Sd16 Door Assembly

- Shantui Sd16 O-Ring

- Shantui Sd16 Track Roller

- Shantui Sd22 Bearing Sleeve

- Shantui Sd22 Friction Disc

- Shantui Sd32 Track Roller

- Sinotruk Engine Parts

- Tow Truck

- Xcmg Bulldozer Parts

- Xcmg Bulldozer Spare Parts

- Xcmg Hydraulic Lock

- Xcmg Transmission

- Yuchai Engine Parts